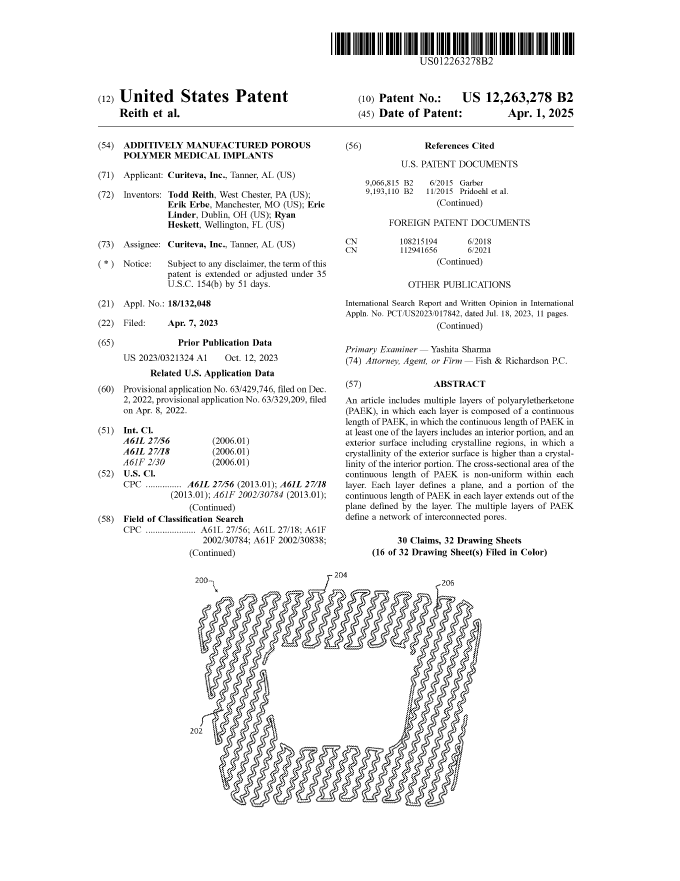

APR 1, 2025

United States Patent Granted, 12,263,278, REITH et al.

Additively Manufactured Porous Polymer Medical Implants

SEP 2024

"Implants Now in Production" - [AM] Additive Manufacturing Magazine September 2024, Volume 13, Number 5

Medical device manufacturer Curiteva is producing two families of spinal implants using a proprietary process for 3D printing porous polyether ether ketone (PEEK).

AUG 2024

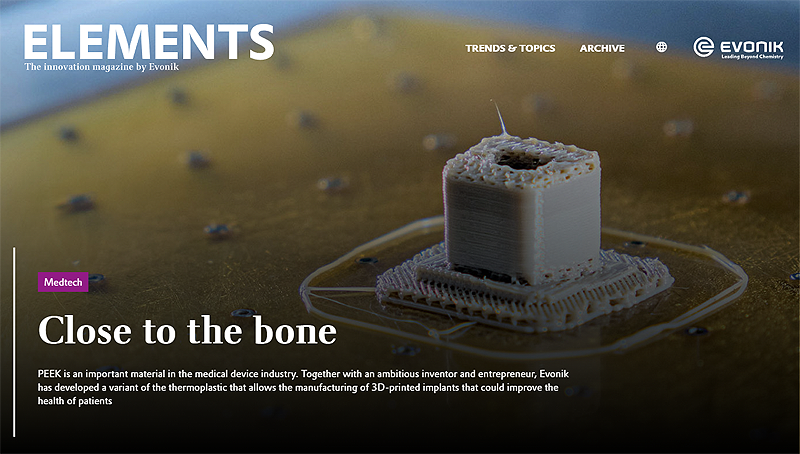

"Quantum leap for spinal implants from the 3D printer" - Elements Audio Interview, Evonik Corporation

Perseverance and the belief in a revolution in orthopaedics: both are driving the inventor and start-up entrepreneur Todd Reith from the USA. Together with Evonik, he has developed a process with which spinal implants can be 3D printed from polyether ether ketone (PEEK).

JUN 15, 2024

"Close to the Bone" - Elements Magazine, Evonik Corporation

Together with an ambitious inventor and entrepreneur, Evonik has developed a thermoplastic, that allows the manufacturing of 3D-printed implants that could improve the health of patients.

JUN 6, 2024

The Cool Parts Show - 3D Printed PEEK Spine Implants in Production

The Cool Parts Show, BONUS episode of #63. The Cool Parts Show visits Huntsville, AL and learns how medical device manufacturer Curiteva is applying a proprietary 3D printing process to produce spine implants from PEEK.

JAN 18, 2024

Curiteva, Inc. Receives FDA 510k Clearance for Inspire™ 3D Porous PEEK HA-FUSE™ Lumbar Interbody System

Curiteva Inc. Announces FDA 510(k) Clearance for Inspire™ 3D Porous PEEK HA-FUSE™ Lumbar Interbody System

SEP 28, 2023

Orthopedics This Week - Curiteva Master Class (Dr. Alex Vaccaro, Dr. Kevin Foley, Barbara Boyan, Ph.D., Erik Erbe, Ph.D.)

Structure Drives Biology, An Evolution in PEEK Implants - How Does 3D Printing Change PEEK implant Performance?

SEP 20, 2023

The Cool Parts Show - Improving Medical Implants with 3D Printed PEEK

The Cool Parts Show, episode #63. 3D Printing medical implants of Polyetheretherketone (PEEK) using a novel printing method called fused strand deposition (FSD).

AUG 2023

[UPDATE] "3D-Printed Porous PEEK Pioneers Reach Spine Market" - Bonezone, Carolyn LaWell

Curiteva developed a fully interconnected and integrated porous interbody system for spinal fusion.

AUG 2023

"Going the Extra 10,000 Miles" - Bonezone, Carolyn LaWell

It was Christmas time, and Todd Reith was traveling with a very important package.

MAR 21, 2023

"3D-Printed Porous PEEK Pioneers Reach Spine Market" - Bonezone, Carolyn LaWell

Todd Reith thought that 3D-printed PEEK could revolutionize the spine industry. With a background as a software and manufacturing engineer, a maker of guitars, expandable titanium implants, and IndyCar parts, he started building a printer in his home lab

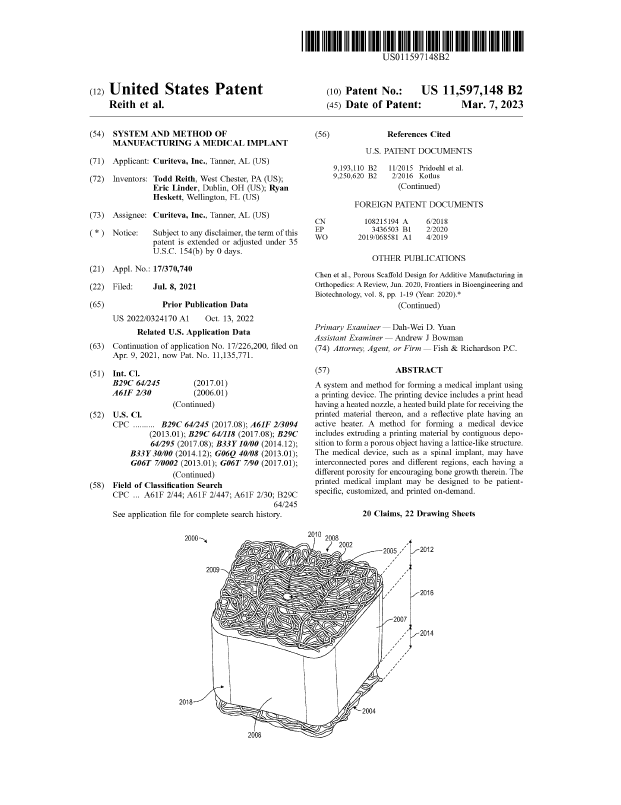

MAR 7, 2023

United States Patent Granted, 11,597,148, REITH et al.

System and Method of Manufacturing a Medical Implant

FEB 13, 2023

Curiteva, Inc. Receives FDA 510k Clearance for Inspire™ 3D Porous PEEK HA-FUSE™ Cervical Interbody System

Curiteva Inc. Announces FDA 510(k) Clearance for Inspire™ 3D Porous PEEK HA-FUSE™ Cervical Interbody System

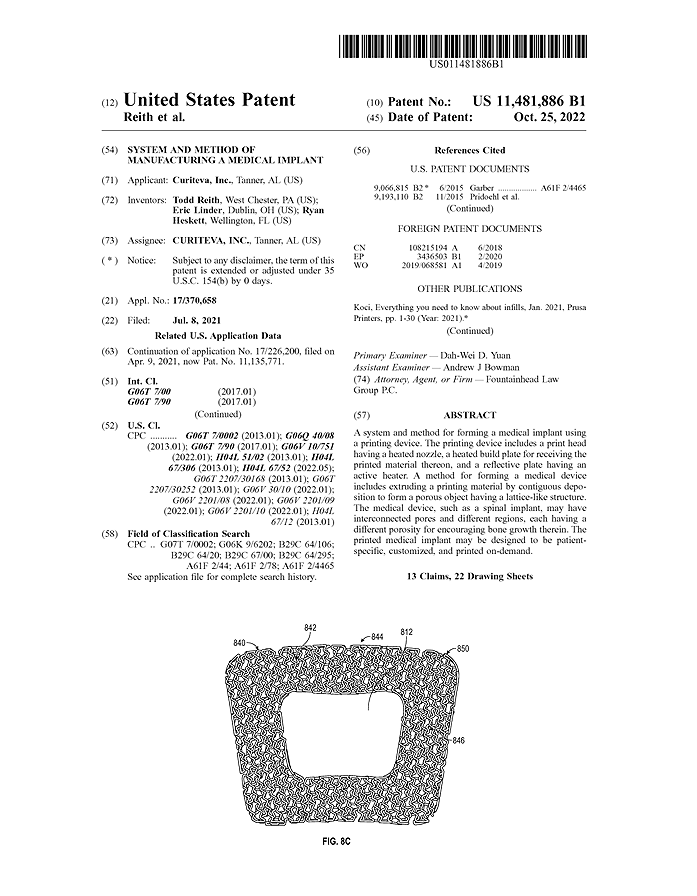

OCT 25, 2022

United States Patent Granted, 11,481,886, REITH et al.

System and Method of Manufacturing a Medical Implant

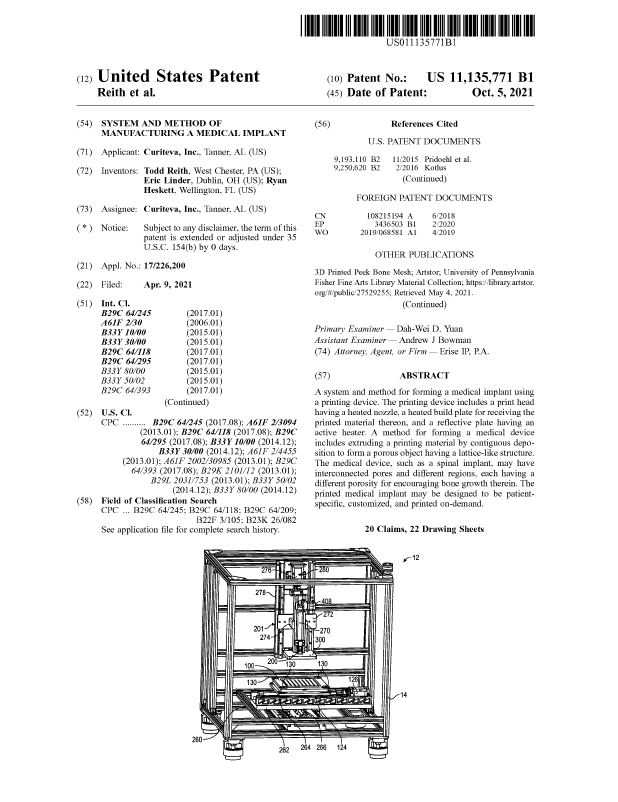

OCT 5, 2021

United States Patent Granted, 11,135,771, REITH et al.

System and Method of Manufacturing a Medical Implant

SEP 11, 2020

Curiteva, Inc. Acquires FossiLabs, LLC:

Redefines Active Implant

Huntsville, Alabama-based spine manufacturer Curiteva announced a marketshifting transaction with the acquisition of FossiLabs, a company focused on the development of Fused Filament Fabrication 3D printed PEEK medical implants.

Redefines Active Implant

MAR 06, 2020

FossiLabs Recognized by Manufacturing Technology Insights

TOP 10 3D Printing Solution Provider 2020

JAN 01, 2020

FossiLabs Offers 3D Printed 'Fully' Porous PEEK Bone-Like Scaffolding Structures

First-of-its-kind 3D printed PEEK porous medical implants with advanced hydrophilicty

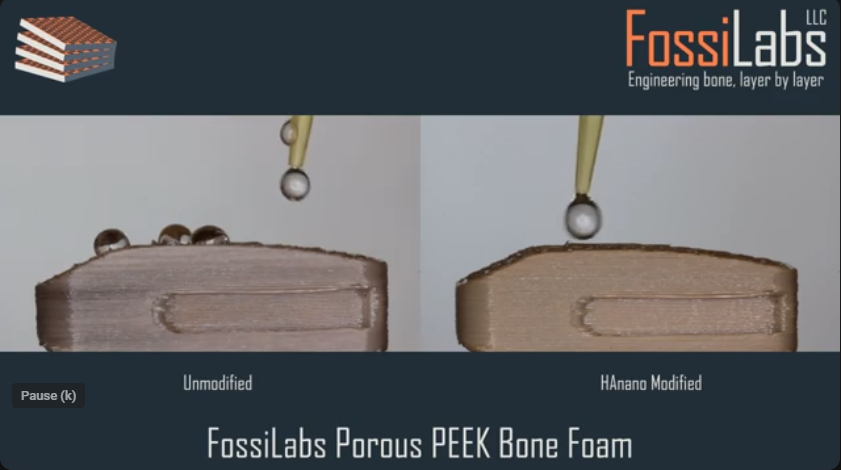

SEP 21, 2019

FossiLabs 3D Printed PEEK Porous Bone HAnano Modified Surface Comparison

FossiLabs first-of-its-kind 3D printed PEEK porous medical implants with defined areas of full porosity and advanced hydrophilicty using HAnano modified surface.

SEP 15, 2019

FossiLabs 3D Printed PEEK Fully Porous Implants

first-of-its-kind 3D printed PEEK porous Bone-FoamTM with advanced hydrophilicty featured at NASS 2019

NASS Annual Meeting, September 25-28, 2019

Evonik Corporation, Booth 2913

Promimic AB, Booth 3901

MAR 1, 2019

FossiLabs Featured 3D Printed Samples

Evonik's VESTAKEEP®world's first implant grade PEEK Filament

AAOS Annual Meeting, March 13-15, 2019

Evonik Corporation, Booth 4417

FossiLabs Featured 3D Printed Samples

Evonik's VESTAKEEP®world's first implant grade PEEK Filament

AAOS Annual Meeting, March 13-15, 2019Evonik Corporation, Booth 4417

Contact Us

SEND US A QUICK MESSAGE